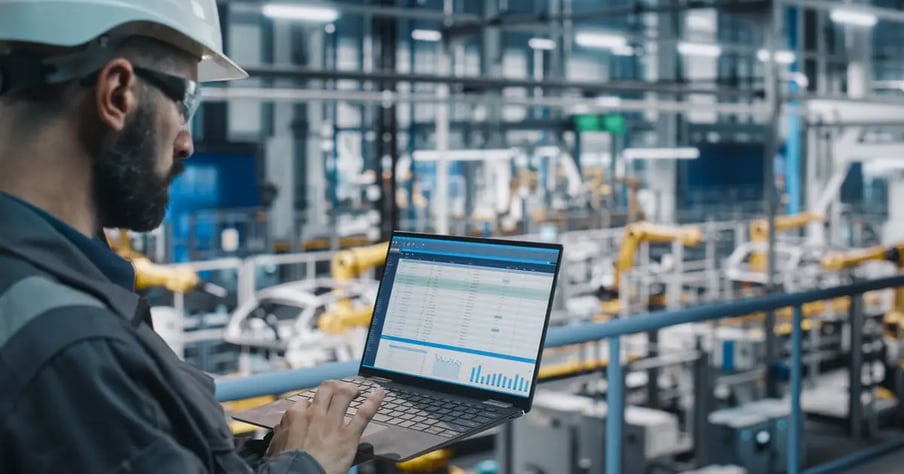

Smart manufacturing is the inevitable course that is currently being charted for all manufacturers.

Manufacturing companies are either undergoing a profound digital transformation, or they are under great pressure to do so. It’s not a choice you have. Implementing smart manufacturing technologies can no longer be ignored.

In this brief article, I will share some of the core elements of smart manufacturing that can propel your industry to the stage of Industry 4.0, and, most notably, I will highlight the role of data management in shaping the future of manufacturing.

Why does manufacturing need to be smart?

The gains of digital transformation and the risk of lagging behind if you don’t up your smart manufacturing game are equally substantial. Basically, smart manufacturing makes you more efficient and helps you save costs. Typical benefits include:

- Reduce machine downtime

- Reduce costs of inventory utilization

- Increase throughput/output

- Improve forecasts

- Increase labor efficiency

If you don’t reach out for these benefits, you can rest assured that your competitors will.

What is Smart Manufacturing?

Smart manufacturing and Industry 4.0 are synonymous. This fourth industrial revolution was obviously preceded by three others. Looking back, it’s quite obvious that no manufacturer would have survived any of those revolutions without adapting; and some probably perished in the transition.

The first industrial revolution was powered by steam, the second harnessed the potential of electricity. The advent of computers marked the beginning of Industry 3.0, also known as the Digital Revolution; and now Industry 4.0, is distinguished by the central role of data, driven by the internet and other forms of connectivity. Rapid advancements in computing power have given rise to a host of emerging technologies.

"The implementation of digital technologies can help accelerate progress towards enterprise goals such as financial returns, workforce diversity, and environmental targets by 22%." (Deloitte, 2020)

Without doubt, successful smart manufacturers are the ones that are best at acquiring, managing, analyzing and sharing data. Characteristic of Industry 4.0 technologies is that they do exactly that: generate, share and/or analyze data. Thus, the huge amount of data that comes along with these technologies, fosters an equivalent need to govern and manage all that data.

The Internet of Things (IoT)

IoT is the core technology of smart manufacturing. It involves connecting machinery, sensors and devices to the internet or cloud, enabling real-time data collection and analysis. The critical question is: What value do you intend to capture through IoT? The use cases are plenty:

- Sensors and connected machines can monitor equipment performance, detect issues and schedule maintenance proactively. This leads to increased productivity, reduced downtime and cost savings.

- Cameras and sensors can be used to inspect products for defects and ensure they meet quality standards. Data from these devices can be analyzed to identify patterns and trends, helping manufacturers optimize production processes, reduce waste and enhance product quality.

- When raw material is reaching a re-order point, inventory triggers can link you to the right onboarded supplier who holds conforming stock.

- GPS trackers and RFID tags can be attached to shipments and inventory items. This enables companies to track the movement and location of goods in real-time throughout the supply chain. Knowing the exact location of products helps in identifying potential disruptions, such as delays due to traffic or weather, and allows for timely adjustments to delivery schedules.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and machine learning technologies play a pivotal role in analyzing and interpreting IoT data. They identify patterns and insights that would be difficult or impossible to discern through manual analysis. With the vast amount of data being generated by IoT devices and other software programs, it is necessary to employ AI to carry out certain routine tasks.

Predictive Maintenance

As a benefit of IoT – not per se a technology – predictive maintenance allows proactive scheduling of maintenance activities based on sensor data and predictive models. Monitoring manufacturing equipment is imperative, and IoT, coupled with smart sensors, enables efficient predictive maintenance. There is no limit to what can be monitored by sensors and analyzed with the right software:

- Temperature

- Vibrations

- Voltage quality

- Battery performance

- Material degradation

Edge Computing

Just like AI, edge computing has gained importance because of the vast amounts of data generated by IoT devices. Edge computing involves data processing and analysis closer to the data source, reducing latency and enabling faster decision-making.

Take a smart camera as an example. The camera can be equipped with a processing unit, making it an edge device. This means that the camera can perform some initial processing of the captured video data right on the device itself, without the need to send everything to the cloud. The smart camera can analyze detected data locally and perform tasks like object recognition or sound pattern analysis in real-time. Based on the analysis, the edge device can take immediate action, such as sending you an alert or activating an alarm, all without needing to wait for a response from a remote server. In this way, edge computing significantly reduces latency because critical decisions are made locally. Edge computing also reduces the amount of data that needs to be transmitted to the cloud. Instead of sending constant video streams, the camera only sends alerts or relevant snippets of video. This reduces bandwidth usage and cloud storage costs.

5G Networks

The deployment of 5G networks is pivotal for the evolution of IoT. 5G provides faster speeds, reduced latency and greater capacity. It is crucial for applications requiring real-time data processing, such as autonomous vehicles. The faster you want your vehicles to move, and the shorter reaction time is needed, the more data needs to be transmitted and processed in real time.

"IIoT will be a $500 billion market by 2025 as advances in its essential technologies drive up demand." (McKinsey & Company, 2021)

Robotic Process Automation (RPA)

RPA involves the use of software robots that employ automation, computer vision and machine learning to execute rule-based and high-volume tasks without human intervention. It's a fundamental enabler for Industry 4.0, reducing defects and waste in the manufacturing process.

The RPA tasks often require extracting data from various sources, such as documents, databases, spreadsheets, emails or websites, and then inputting that data into other systems or applications. Effective data management is essential to ensure that the data extracted is accurate, complete and formatted correctly before it is processed by the RPA bot.

Furthermore, RPA bots often need to validate and verify data to ensure its accuracy and consistency. For example, when processing invoices or customer orders, RPA bots may need to cross-reference data against predefined rules, perform calculations or compare it with existing records. Proper data management practices help maintain data integrity and enable RPA bots to make reliable decisions based on the information they handle.

Digital Twin

A digital twin is a virtual representation of a real-world asset, process or system. It replicates its appearance and behavior, benefiting product development, factory planning or assessing potential changes. This can be particularly helpful if you operate high-end equipment.

Take an airline company operating aircrafts as an example. To ensure the safety and efficiency of its operations, the airline creates digital twins for each aircraft in its fleet. Each aircraft is equipped with various sensors and data collection systems that create a corresponding digital twin for every physical aircraft. This digital twin is a virtual representation of the actual airplane, mirroring its physical characteristics, components, and systems. The digital twin continuously synchronizes with the real aircraft by receiving data from sensors onboard the plane. This data includes information on engine performance, fuel consumption, structural health, temperature, pressure and more.

The digital twin allows engineers to simulate various scenarios and what-if analyses. For example, they can test the impact of different flight conditions, weather events, or maintenance schedules on the aircraft's performance and longevity.

The digital twin can also be used for training pilots and maintenance crews. It provides a realistic simulation environment where trainees can practice handling different situations and emergencies.

Augmented Reality (AR)

Augmented reality is related to the digital twin. It blends digital information with the real world, enhancing interactivity and providing an enriched experience of the physical environment. It's particularly beneficial in maintenance and training scenarios. For example, AR can provide assembly line workers with visual instructions and guidance overlaid onto physical objects. Workers can wear AR glasses or use mobile devices with AR apps to see step-by-step instructions, reducing errors and improving efficiency.

Cloud Technologies

Given the vast amount of data collected by IoT, scalable and cost-effective cloud platforms are essential for centralizing and managing diverse data sources. Cloud technologies facilitate real-time processing and analysis of streaming data.

Master Data Management (MDM) – Breaking down the silos

The commonality of IoT and RPA devices and programs is that they generate vast amounts of volatile data. To harness that data and make it useable across departments, a platform to store and govern data in a generalized and unified manner is needed.

This is a huge deal that is often overlooked in smart manufacturing endeavors. According to Gartner only 32% of the digital supply chain roadmaps that do exist are aligned under a single governance process and to common business goals. (Gartner: Supply Chain Technologies and Digital Transformation)

Siloed data infrastructures are among the most common reasons to failed digital transformation projects. A lack of unified and easily accessible data makes it hard to integrate new data-generating technologies.

What are data silos, and why are they problematic?

A centralized platform with multidomain and data governance capabilities can secure data quality, streamline data sharing and create a single version of truth across product, customer, supplier, asset and location data. This provides a context for your IoT data. IoT data is always data about an asset. This means to be able to understand sensor data correctly, you need firm knowledge about the monitored assets, i.e., its master data.

“Platforms are helpful because they abstract a lot of common functions away from the specific application logic. Application developers just want to focus on the specific problem they are solving and use common capabilities for computing power, storage, or security. A good platform thus dramatically reduces the cost of developing and maintaining applications.” (McKinsey & Company, 2021)

Master data management helps you build the data foundation you need to fuel AI, IoT, digital twins, RPA and other smart manufacturing initiatives.

There’s a lot of Industry 4.0 technologies that can help futureproof your business. But the real question you need to ask is this: What data do you need, and how can you harness it?